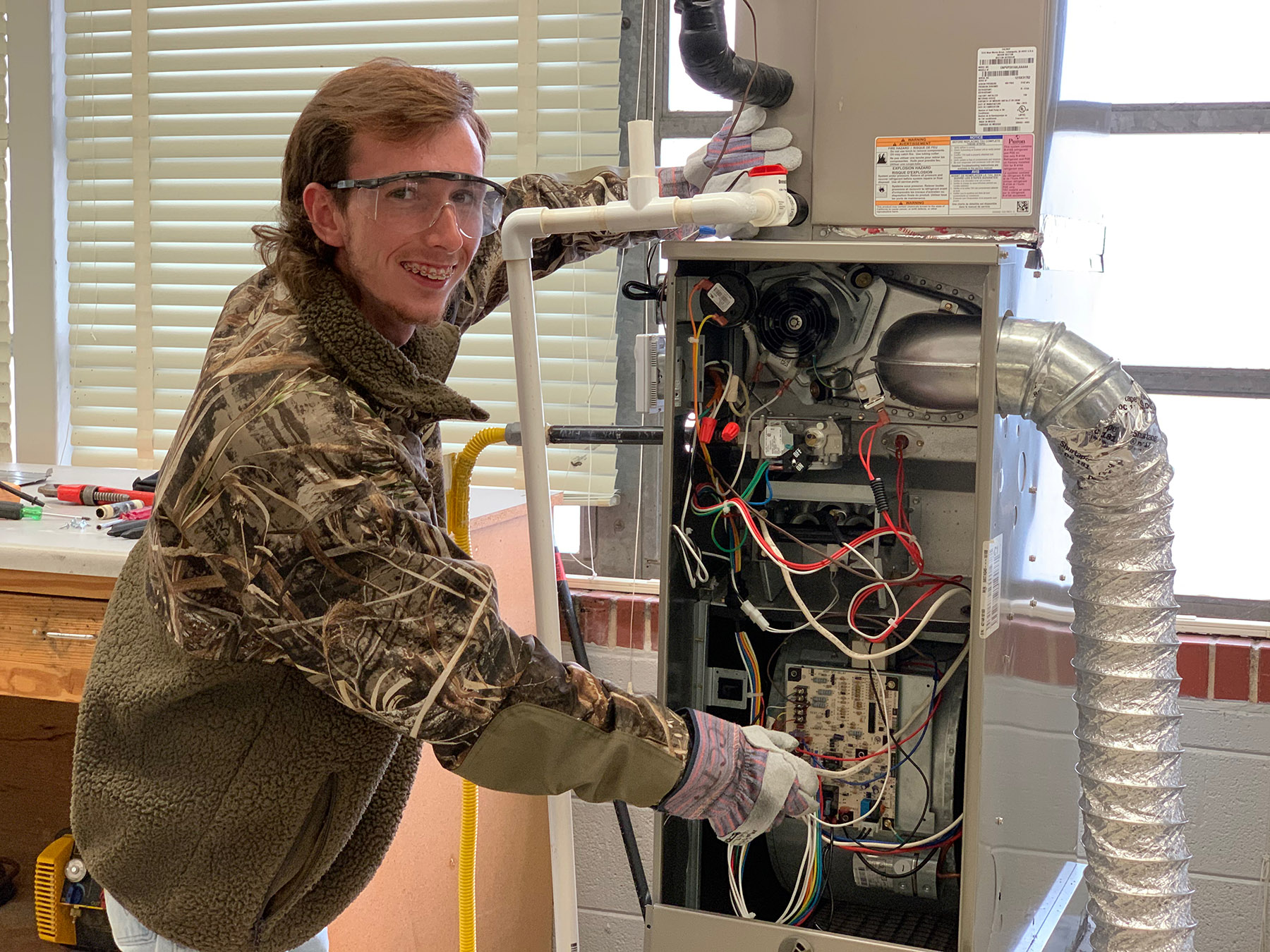

Welcome to

AC & Refrigeration

Course Overview

Learn the theory and principles of air conditioning and refrigeration through practical experience. Get a hands on introduction to professional tools and practice trouble-shooting procedures. You will have the opportunity to obtain important industry certifications such as EPA and NCCER.

- Work-Based Learning

- Enriched

- Industry Certification: NCCER Level 1

Hello! I’m Mr. Yoakum. Have questions? Interested in HVAC?